Innovation / R&D

Pioneering Research and Development

Our cutting-edge R&D facility drives innovation in electric mobility solutions. Equipped with advanced tools and technologies, our product development process emphasizes robust design reviews, including Design and Process FMEA (Failure Mode and Effects Analysis) to ensure optimal performance and reliability. We also focus on Design for Manufacturing (DFM) to achieve cost optimization without compromising quality. This holistic approach enables us to create efficient and sustainable electric motor and controller systems tailored to the needs of the electric vehicle industry.

R & D Validation Facility

Environmental Chamber

Environmental Chamber

- The ET600 is often used for measuring and analyzing environmental parameters such as Hot temperature(180°C), Cold temperature(-40°C) And humidity(95%), This helps in assessing environmental conditions and ensuring compliance with regulatory standards.

- This Environmental chamber uses to test our various products such a EV Power train motors, controllers and chargers possible to simulate the various environmental conditions (This will helps to improve the Reliability of our products)

- Various type of environmental simulation with based on our requirement simulation hours possible to test.

Dust Chamber

Dust Chamber

- Ingress Protection Testing (IP Testing): To evaluate the resistance of electronic devices, components, and enclosures to dust ingress. This helps determine if products meet specific IP (Ingress Protection) ratings, such as IP5X or IP6X, which indicate varying levels of dust resistance.

- For research and development purposes, enabling engineers and scientists to design and test products with better dust resistance. This can lead to innovations in materials and designs that improve durability in harsh environments.

- The dust chamber is designed to test a product's resistance to extremely dusty, desert-like settings. It can meet certain automotive test standards. Intermittently, powerful blowers blast compressed air through finely powdered dust, allowing the particles to settle and cover the product.

- Dust chambers are essential for validating the performance and reliability of products and components that will be exposed to dusty environments, ensuring they meet the required standards and perform optimally in real-world conditions.

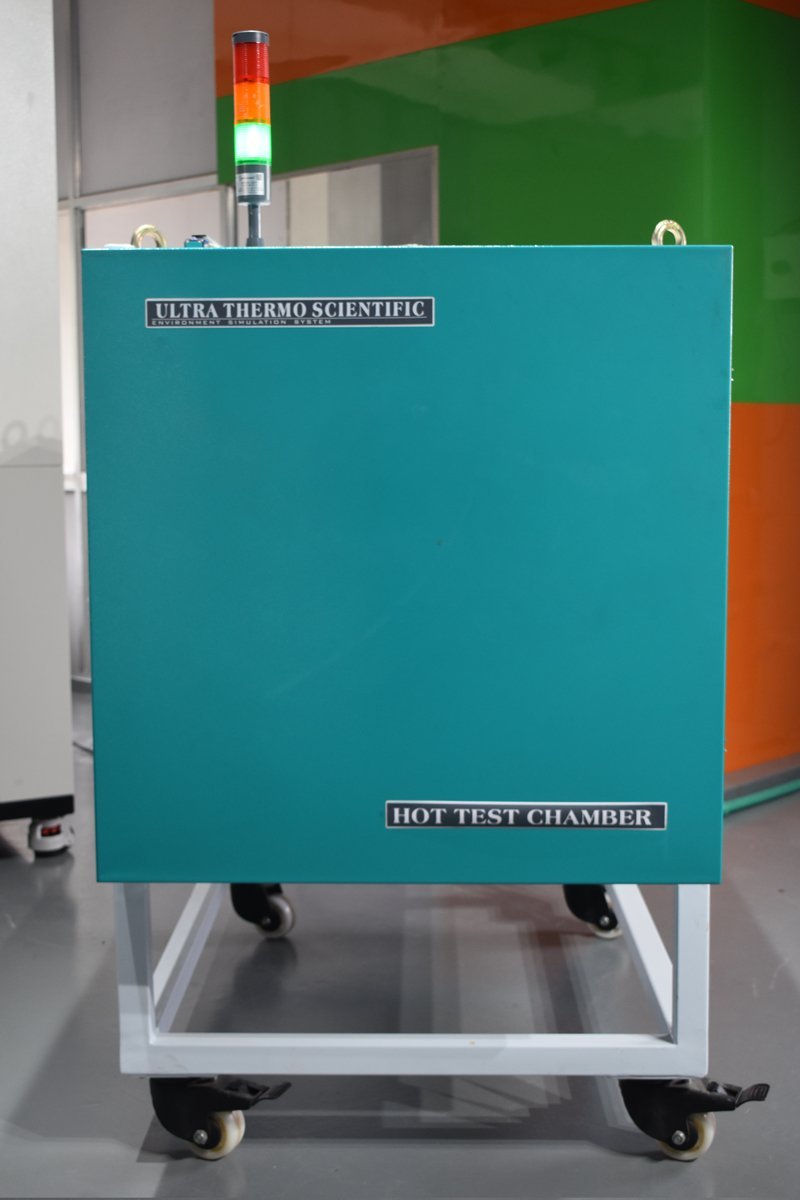

Hot Test Chamber

Hot Test Chamber

To evaluate how materials, including metals, plastics, and composites, behave under high temperatures. This can include checking for thermal stability, expansion, and degradation.

- To ensure that manufacturing processes produce parts that can withstand high temperatures, which is particularly important in industries like automotive, and electronics.

- For developing new materials or products by studying how they react to high temperatures and refining their designs accordingly.

- Surface Flux density Measurements

- Bh & Br Characterization

- Stator Tooth, Various types of electromagnetic coils,and Surface flux density measurement.

- All type of magnets like neodymium iron boron (NdFeB), samarium cobalt (SmCo), alnico, and ceramic or ferrite magnets possible to take overall magnetic performance.

Upcoming Projects

- Electric Marine Motors

Developing eco-friendly electric motors for marine vehicles, focusing on efficiency and sustainability.

- Drone Motors

SPR EMFI is designing small, powerful motors for drones, ensuring precision and high thrust for aerial applications.

Future Technologies

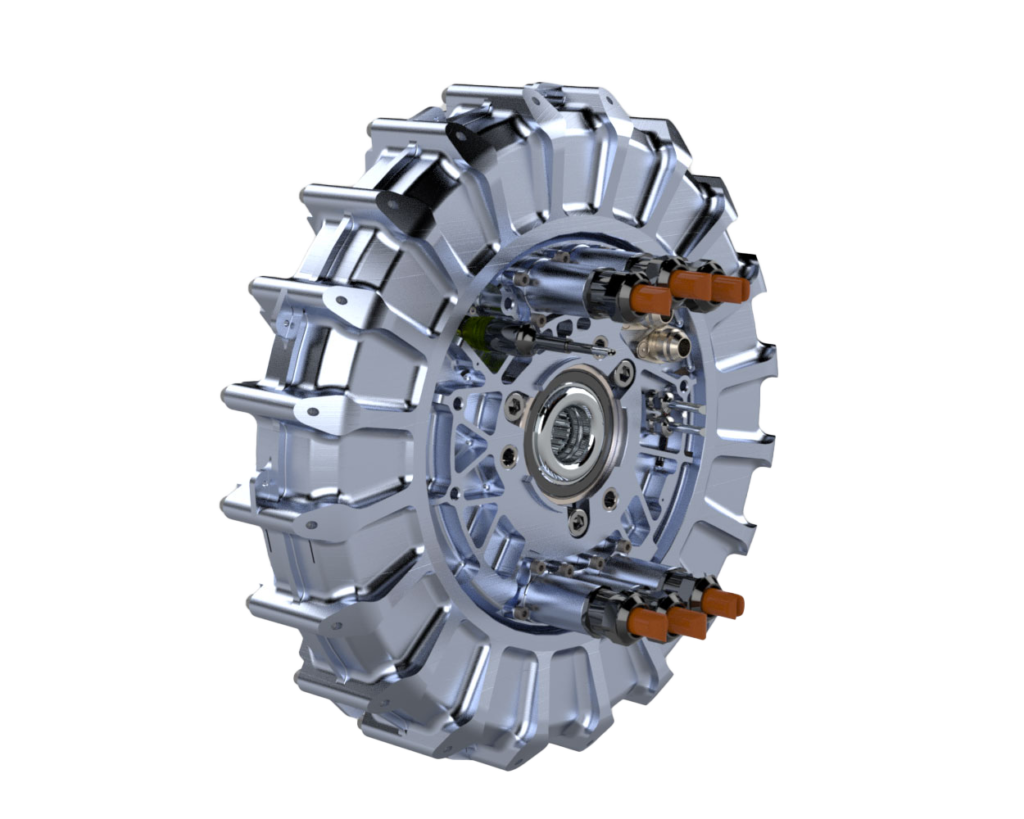

- Axial Flux Motors

Offering a compact, high-torque solution ideal for in-wheel and space-constrained applications.

R & D Testing Facility

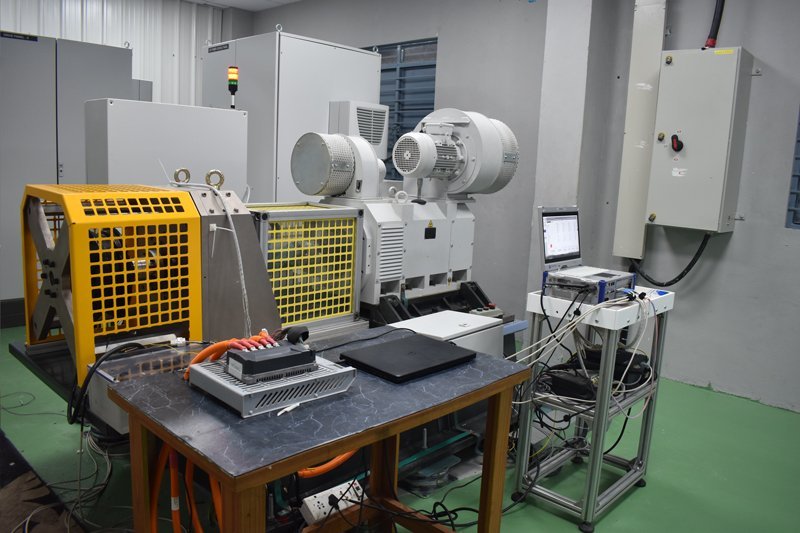

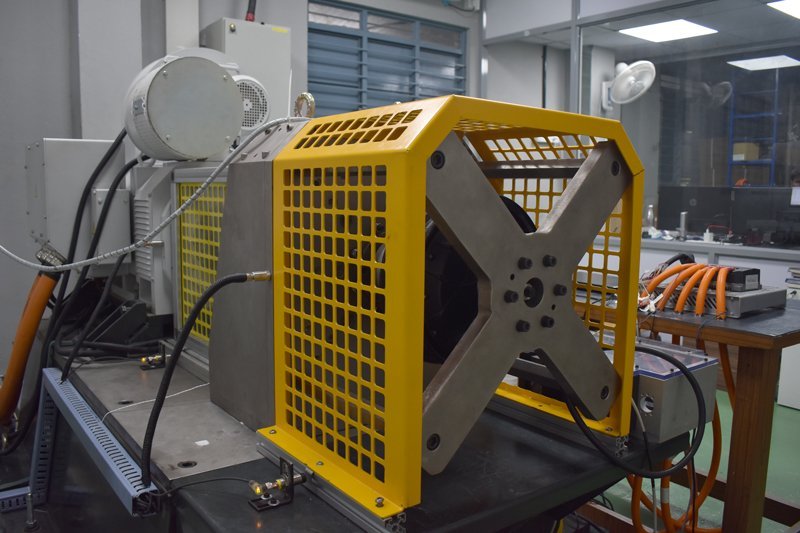

Powertrain Test Rig

Powertrain Test Rig

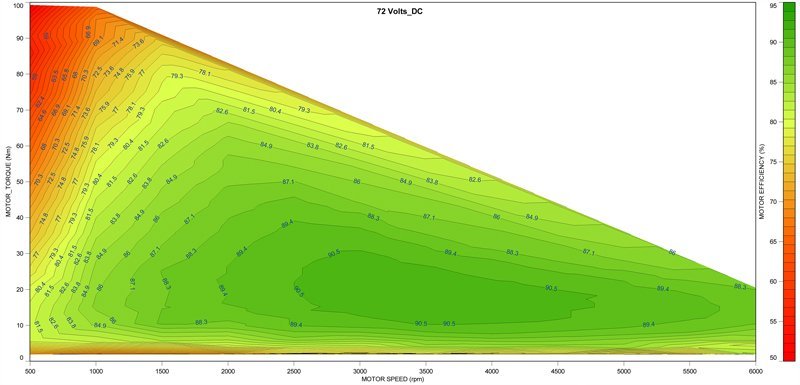

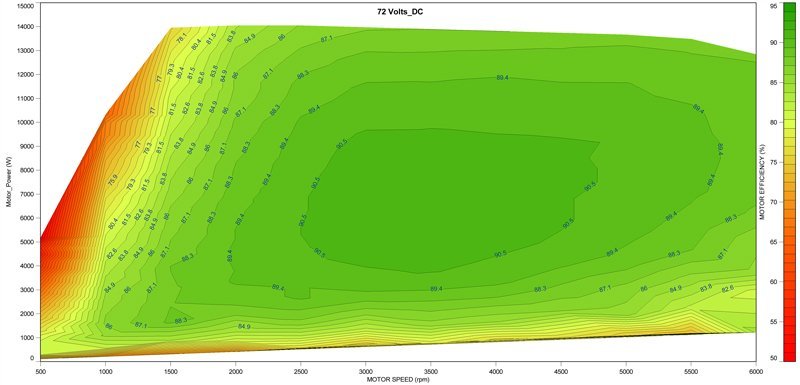

Transient dynamometers can accurately measure the performance characteristics of EV motors, such as torque, speed, and power output. We can test the motors under various load conditions and speeds to assess their performance and efficiency.

In the automotive industry, transient dynamometers are used to evaluate motor performance under real-world driving conditions. This includes assessing how the motor responds to sudden changes in throttle, acceleration, and braking. These measurements help in optimizing motor calibration for better performance and Efficiency.

It can simulate different driving conditions to assess how these new technologies perform under dynamic loads.

- Performance Mapping (Torque and Speed).

- Back EMF, Cogging Torque, Torque Ripple, Friction losses Test.

- Efficiency Mapping.

- Thermal performance test.

- Regeneration efficiency and Performance mapping.

- Durability Testing.

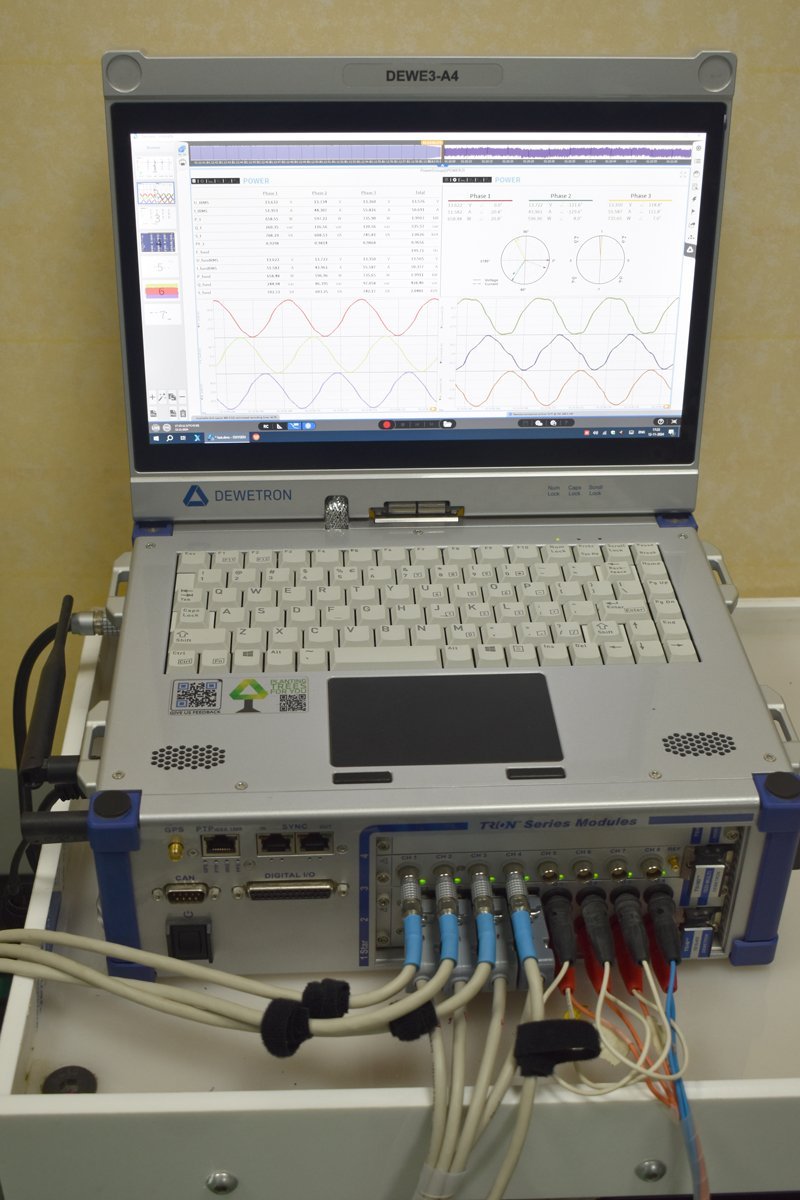

Power Analyzer

Power Analyzer

- High-Speed Data Acquisition: Capable of handling high-speed measurements, which is crucial for capturing dynamic events and rapid changes in motor performance.

- Modularity: Allows for customization with various input modules to accommodate different types of sensors and measurements required for comprehensive motor testing.

- Real-Time Data Processing: Facilitates real-time monitoring and analysis, enabling immediate feedback and adjustments during testing.

- It can also accommodate the Different types of Temperature sensors and torque sensor measurement, and it stores the real time data and over all motor, controller and battery performance mapping also possible with this instrument.

Flux meter

Flux meter

The Lake Shore 480 Flux meter is an advanced instrument designed for measuring magnetic flux density. It is particularly useful in applications involving low-level magnetic fields and high-precision measurements.

- Overall Magnetic Field Measurements

- Material Characterization

- Surface Flux density Measurements

- Bh & Br Characterization

- Stator Tooth, Various types of electromagnetic coils,and Surface flux density measurement.

- All type of magnets like neodymium iron boron (NdFeB), samarium cobalt (SmCo), alnico, and ceramic or ferrite magnets possible to take overall magnetic performance.